Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Elevate your 3D prints with TRONXY’s metallic magic — where precision meets power!

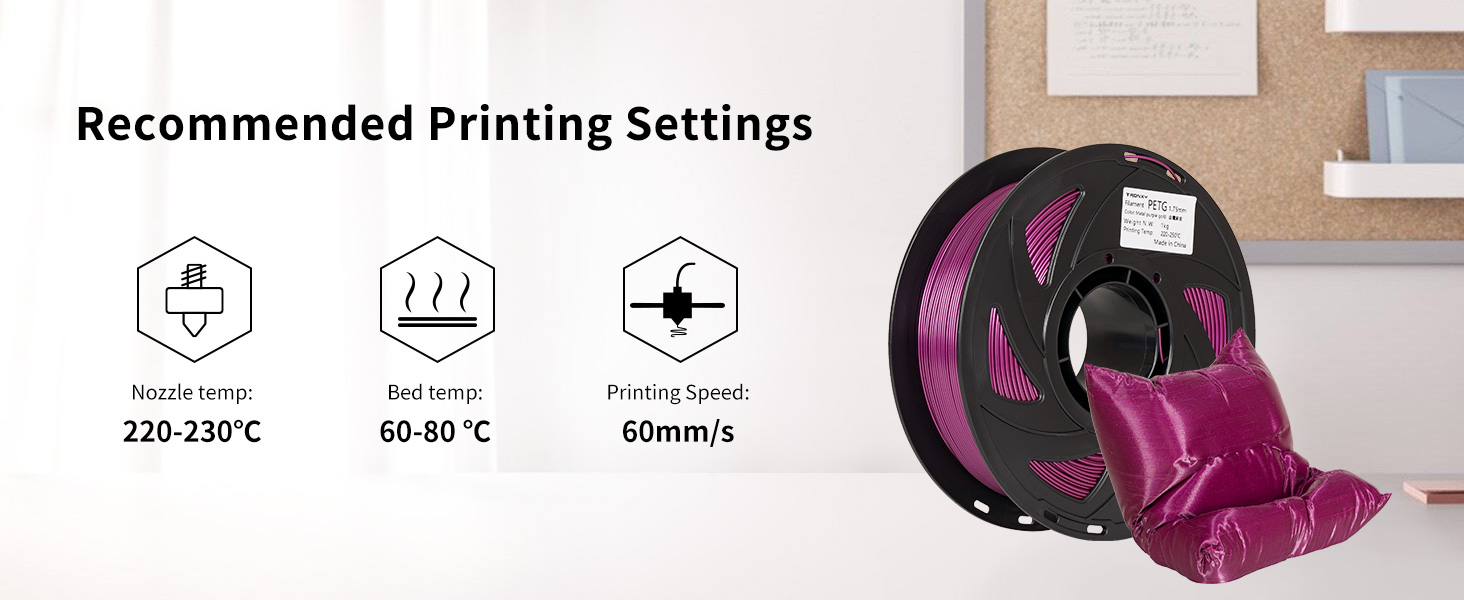

TRONXY PETG Filament 1.75mm Metal-Magenta-Gold offers a 1KG spool of high-quality PETG with ±0.05mm diameter accuracy. Engineered for toughness and thermal resistance, it excels in printing large, warp-resistant mechanical parts with excellent bed adhesion. Its unique blend of strength and flexibility makes it a top choice for professional-grade indoor and outdoor 3D printing projects.

| ASIN | B0D4YGHBFT |

| Best Sellers Rank | #20,955 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #541 in 3D Printing Filament |

| Brand | TRONXY |

| Color | Metal-gold |

| Customer Reviews | 3.4 3.4 out of 5 stars (1,635) |

| Date First Available | May 23, 2024 |

| Item Weight | 2.2 pounds |

| Item model number | US-metal-gold |

| Manufacturer | TRONXY |

| Manufacturer Part Number | metal-gold |

| Material Type | Polyethylene Terephthalate Glycol |

| Number of Items | 1 |

| Package Dimensions | 8.19 x 8.03 x 2.6 inches |

A**A

Great color, easy to print, even with a bowden tube, but it takes practice.

I am not new to 3d printing, but i am new to TPU. i have had a Monoprice Select Mini 3d printer for about 2 years and recently added a Tronxy X5SA-400 printer. Despite all my printing i had never tackled TPU. i have been told that it is next to impossible to print TPU on a bowden type printer, which my first printer was. after i installed my new printer i thought i would try my hand at it. i loved my new Tronxy printer so i decided to give their filament a try. the price was right, and i wanted to print several cosplay items for my daughter. the filament ships quickly from amazon, and comes in the standard sealed filament pouch. i opened it up and checked it out. TPU is different than anything i have used before. the filament feels more like a rubber band then a piece of plastic. my printer has a titan geared extruder with a 630mm bowden tube and i thought loading it in to the titan was going to be a nightmare, but it was surprisingly easy, easier then i find most PLA's. i figure it is because it is flexible that it goes where the extruder wants instead of where it wants. i loaded the filament and extruded a bit. at my nozzle temp of 230 it came right out no issue. unfortunately with a little retraction, it kept oozing out. as discovered, this is the nature of TPU. retraction is almost useless, and does more harm then good most of the time. after some reading about printing flexible filaments, i found they needed to be printed slowly. <30mm/s. cooling can help with stringing and oozing, but wont fix it. turn retraction off, make speedy travel moves. i sliced my file up accordingly and set it to print. my favorite surface to print on is Kapton tape and i have coated my bed with it. i give it a light spray of aquanet hair spray, but i find that filaments just stick to it. it was no different with this TPU. it had excellent bed adhesion. as it printed i did find a lot of stringing. speedy travel moves helped a bit, but there was a lot of post processing needed. the processing was simple, i used some wire snips to clip the strings. but in the end i was very happy with my results. on subsequent prints i found that temperature control is very important. the tronxy tpu seemed to print just fine in the 205 degree range, with plenty of layer adhesion. tho it is important that you have a heated bed. one of my sliced files allowed my bed to drop to 35 degrees and the print pealed right off. i suggest you print a temperature tower or other files that help you tune filament settings as it will help you find a sweet spot . all in all the filament gets an A rating from me. i will definitely be getting more flexibles in the future , and the tronxy TPU seems very high quality. just follow some simple techniques and your prints will be just as good.

R**.

Inconsistent filament diameter causing failure to feed in multiple printers and pens.

The filament right off the roll when held straight has many bends and narrow spots that you can't only see but can also feel when it's run through your hand. This has cause feed problems via failure to feed. No jams just spots the cause the worm driven gear to slip just enough to chew a pit into the filament enough that it won't grab it until you manually push it further. This isn't only a problem in printers this has been the same problem in multiple pens also. Is it just my roll? Is the all of the rolls? Or is it in some magical way that all of my equipment is screwed up.. The speed, feed rate, and nozzle size has not made a difference with this stuff. I regret spending the money on this specific abs because I've never had a problem with any other brand I have used. Now I have a useless spool sized paperweight that I cannot use for anything productive. I'd avoid this abs and maybe even this brand because it's very visually obvious that they don't have QC on the diameter.... I'm editing my review just a few minutes after I initially wrote it. I have now included pictures showing how all of my feed mechanisms have chewed deep ruts into it. First pic is of a rut chewed into it by a printer now Im only showing one of each because I've had the same problem when trying to use this filament in any printer or pen at any speed with different Temps and different nozzles.. Second pics show how the tooth marks are double and tripled because the feeds have slipped on this abs. Third pic is showing it fresh off the reel the best I could so you can see the warps in it. I'm not trying to be hateful and I wish someone would contact me. Using 3D printers and pens is a very new hobby that I had to pick up because I can no longer mountain bike or hike due to bone spurs growing through my vertebral disc's and it can't be cured. I honestly just wanted to make a stupid change bank for my son who lives across the country before I have to get surgery on my lower back that has high risk. He has a specific idea on what he wanted and I know exactly how to make it but I need decent filament. I don't want pity either I just wanted to convey that this set back has taken time that I can get back and now I have to purchase new filament in hope that another brand lives up to it claims..

M**X

Good Stuff. I found it a little stringy but I think it was more the way the parts printed than the material

M**S

The best place I have found thus far for the Dremel 3D20.

B**K

Very nice filament. Prints nice and looks good. “Glow in the dark “ not that glowy but it does glow.

3**D

ここ一年位ずっと購入しています。そのうち少なくとも3回は材料の変更があり、その都度設定を見直してきました。現在の素材だとノズル温度90度、ベッドの温度60度で安定しています。糸引きはありますが、問題ない程度です。 スピードに関して工夫が必要ですが、基準より早めでも対応する感じがあります。ノズル詰まりの原因解消として部屋の室温を下げるのもおすすめです。

あ**や

姪っ子のために使いました。ブラックライトにあてると光るので喜んでました。

Trustpilot

1 week ago

3 days ago